Converting Synchro Signals to Pulse-Width-Modulation Signals.

Table of Contents

- Introduction

- Understanding Synchro Signals

- 2.1 Origin and Applications

- 2.2 Signal Characteristics

- Overview of Pulse-Width-Modulation (PWM)

- 3.1 Basics of PWM

- 3.2 Applications of PWM

- The Need for Synchro to PWM Conversion

- 4.1 Benefits of Integration

- 4.2 Challenges in Integration

- Technology Overview

- 5.1 Synchro Converters

- 5.2 PWM Technology

- 5.3 Converting Synchro Signals to PWM

- Implementation of Synchro to PWM Conversion

- 6.1 Hardware Requirements

- 6.2 Software Requirements

- 6.3 Integration Process

- Benefits of Synchro to PWM Conversion

- 7.1 Enhanced Precision

- 7.2 Improved Reliability

- 7.3 Cost-Effectiveness

- 7.4 Scalability

- Applications of Synchro to PWM Conversion

- 8.1 Aerospace and Defense

- 8.2 Industrial Automation

- 8.3 Telecommunications

- 8.4 Marine Navigation

- Challenges and Solutions

- 9.1 Data Integrity

- 9.2 Compatibility Issues

- 9.3 Latency Concerns

- Future Trends in Synchro to PWM Conversion

- 10.1 Technological Advancements

- 10.2 Increased Adoption Across Industries

- 10.3 Integration with IoT and Industry 4.0

- Conclusion

- References

1. Introduction

The convergence of different signal types in modern technology is essential for enhancing the performance and compatibility of various systems. Synchro systems, known for their precise angular position sensing, often need to be integrated with pulse-width-modulation (PWM) systems for applications that require precise control. This white paper explores the process of converting synchro signals to PWM signals, detailing the benefits, challenges, and applications of this conversion. By understanding the intricacies of synchro to PWM conversion, organizations can optimize their control systems for improved accuracy and reliability.

2. Understanding Synchro Signals

2.1 Origin and Applications

Synchro systems, also referred to as synchronous resolvers, have their origins in early 20th-century military and aerospace applications. These systems are designed to provide precise angular position measurements, which are critical for navigation, control, and guidance systems. Over time, the use of synchro systems has expanded to include various industries such as industrial automation, robotics, and other fields that require accurate position feedback. Synchro systems are valued for their reliability, precision, and ability to provide continuous analog data.

2.2 Signal Characteristics

Synchro signals are three-phase AC voltages that are proportional to the sine and cosine of the shaft angle. This characteristic enables synchro systems to measure and transmit angular position with high accuracy. The signals are generated by rotating machinery, where the primary (excitation) voltage induces secondary (output) voltages. The amplitude of these secondary voltages corresponds to the rotor’s position, providing a direct and continuous relationship between the electrical signal and the mechanical angle. The analog nature of synchro signals ensures smooth and precise data transmission, which is essential for applications demanding high accuracy.

3. Overview of Pulse-Width-Modulation (PWM)

3.1 Basics of PWM

Pulse-width modulation (PWM) is a technique used to encode a message into a pulsing signal. It is widely used for controlling power to inertial electrical devices, making it ideal for various applications, including motor control, light dimming, and signal modulation. PWM works by varying the width of the pulses in a pulse train, where the width of the pulses corresponds to the desired value. By adjusting the duty cycle (the ratio of the pulse width to the period), PWM can effectively control the amount of power delivered to a device.

3.2 Applications of PWM

PWM has a broad range of applications due to its efficiency and precision:

- Motor Control: PWM is commonly used to control the speed and torque of motors in various applications, from industrial machinery to consumer electronics.

- Light Dimming: PWM is used in LED dimming and other lighting applications to adjust brightness levels smoothly.

- Signal Modulation: PWM is employed in communication systems to encode data for transmission.

- Power Delivery: PWM is used in power supplies and converters to regulate voltage and current levels.

4. The Need for Synchro to PWM Conversion

4.1 Benefits of Integration

Integrating synchro signals with PWM systems offers several benefits:

- Enhanced Data Communication: Converting synchro signals to PWM format allows for seamless integration with modern control systems, facilitating real-time monitoring and control.

- Improved System Compatibility: By converting synchro signals to PWM, legacy synchro systems can interface with contemporary digital control systems, extending their usability and enhancing interoperability.

- Increased System Flexibility: The integration enables flexible system design, allowing the use of synchro data in various applications without significant modifications to existing infrastructure.

4.2 Challenges in Integration

While the benefits are significant, integrating synchro signals with PWM systems also presents challenges:

- Signal Conversion Complexity: The conversion process requires precise handling of synchro signals to maintain accuracy.

- Compatibility Issues: Ensuring compatibility between synchro systems and PWM interfaces can be complex.

- Latency Concerns: Minimizing latency in data transmission is critical for real-time applications.

5. Technology Overview

5.1 Synchro Converters

Synchro converters are devices that translate synchro signals into other formats, such as PWM signals. These converters typically sample the synchro signals at high rates, digitize them using analog-to-digital converters (ADCs), process the data, and then convert it to PWM signals suitable for use with digital control systems.

5.2 PWM Technology

PWM technology involves using pulses of varying widths to encode information or control power delivery. The duty cycle of a PWM signal determines the average power delivered to a load. PWM signals are generated using digital controllers or dedicated PWM generators, which can produce precise and adjustable pulse widths.

5.3 Converting Synchro Signals to PWM

Converting synchro signals to PWM involves several steps:

- Signal Sampling: Synchro signals are sampled at a high rate to capture accurate positional data.

- Analog-to-Digital Conversion: The sampled analog signals are converted to digital format using ADCs.

- Data Processing: The digital data is processed to ensure accuracy and suitability for conversion to PWM.

- PWM Generation: The processed digital data is used to generate PWM signals using digital controllers or dedicated PWM generators.

6. Implementation of Synchro to PWM Conversion

6.1 Hardware Requirements

Implementing synchro to PWM conversion requires specific hardware components:

- Synchro Converter: The primary device that samples, digitizes, processes, and converts the synchro signals to PWM.

- ADC (Analog-to-Digital Converter): Converts the analog synchro signals into digital data.

- PWM Generator: Converts the processed digital data into PWM signals.

- Microcontroller or FPGA: Processes the digital data and manages the conversion process.

6.2 Software Requirements

The software component involves drivers and applications that facilitate data transfer and interpretation:

- Device Drivers: Ensure the operating system can communicate with the synchro converter.

- Data Processing Software: Applications that process and visualize the converted data.

- Firmware: Embedded software in the synchro converter that controls its operation and data transmission.

6.3 Integration Process

Integrating synchro to PWM conversion involves several steps:

- Installation of Hardware: Connect the synchro converter to the synchro system and the PWM interface.

- Driver Installation: Install the necessary drivers on the computer or digital system.

- Configuration: Configure the synchro converter and software for optimal performance.

- Testing: Verify the system’s functionality through rigorous testing to ensure accurate data transmission.

7. Benefits of Synchro to PWM Conversion

7.1 Enhanced Precision

The high accuracy of synchro signals, combined with the robustness of PWM technology, ensures precise data transmission and control. This precision is crucial for applications requiring exact positional information, such as navigation and industrial automation.

7.2 Improved Reliability

PWM technology’s resistance to noise and interference enhances the reliability of data transfer in harsh environments. This reliability is particularly important in aerospace, defense, and industrial applications where data integrity is critical.

7.3 Cost-Effectiveness

By leveraging existing PWM infrastructure, the integration reduces the need for costly upgrades or replacements of synchro systems. This cost-effectiveness makes it feasible to extend the life of legacy systems while integrating them with modern technology.

7.4 Scalability

The ability to connect multiple devices on a PWM network allows for scalable system designs, accommodating future expansions and upgrades. This scalability is beneficial for systems that need to grow or adapt to changing requirements over time.

8. Applications of Synchro to PWM Conversion

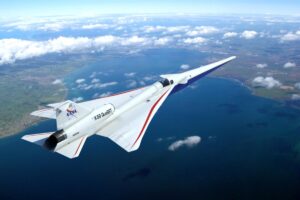

8.1 Aerospace and Defense

In aerospace and defense applications, synchro to PWM conversion facilitates the integration of navigation, radar, and control systems, ensuring accurate positional data transmission. This integration is essential for the precise operation of aircraft, missiles, and other defense equipment.

8.2 Industrial Automation

In industrial settings, synchro converters enable precise control of machinery and robotics, enhancing operational efficiency and accuracy. The integration of synchro signals with PWM systems allows for advanced automation and control strategies, improving productivity.

8.3 Telecommunications

Synchro to PWM conversion supports the synchronization of communication systems, ensuring reliable and synchronized data transfer across networks. This is essential for maintaining the integrity and performance of telecommunications infrastructure.

8.4 Marine Navigation

In marine navigation, synchro converters provide accurate heading and positional data to navigation systems, enhancing safety and operational efficiency. The integration of synchro signals with PWM systems ensures reliable data transmission even in harsh marine environments.

9. Challenges and Solutions

9.1 Data Integrity

Challenge: Maintaining data integrity during the conversion process is crucial to ensure accurate and reliable data transmission. Any loss or corruption of data can lead to significant errors, particularly in applications requiring high precision.

Solution: Implementing robust error-checking and correction mechanisms during the analog-to-digital conversion and PWM generation processes can mitigate data integrity issues. Additionally, using high-quality synchro converters and ADCs can ensure the accuracy of the converted data.

9.2 Compatibility Issues

Challenge: Ensuring compatibility between synchro systems and PWM interfaces can be complex, given the differences in signal formats and data transmission protocols.

Solution: Utilizing standard communication protocols and ensuring proper configuration of the synchro converters can address compatibility issues. Comprehensive testing and validation during the integration process can also help identify and resolve potential compatibility problems.

9.3 Latency Concerns

Challenge: Minimizing latency in data transmission is critical for real-time applications. Any delays in converting and transmitting synchro signals can impact the performance of the synchronization system.

Solution: Optimizing the conversion and transmission processes by using high-speed ADCs, efficient data processing algorithms, and fast PWM generators can reduce latency. Additionally, ensuring that the synchro converter and PWM interface are appropriately configured for low-latency operation can enhance real-time performance.

10. Future Trends in Synchro to PWM Conversion

10.1 Technological Advancements

The continued advancement of PWM technology, including higher data transfer rates and improved power delivery, will further enhance the integration of synchro systems with PWM interfaces. Innovations in ADC technology and data processing algorithms will also contribute to more efficient and accurate synchro to PWM conversion.

10.2 Increased Adoption Across Industries

As more industries recognize the benefits of integrating legacy systems with modern PWM infrastructure, the adoption of synchro to PWM conversion is expected to increase. This trend will be driven by the need for precise and reliable data transmission in applications ranging from aerospace to industrial automation.

10.3 Integration with IoT and Industry 4.0

The rise of the Internet of Things (IoT) and Industry 4.0 is driving the demand for seamless connectivity and data integration across various systems. Synchro to PWM conversion can play a vital role in this context by enabling legacy synchro systems to connect with IoT devices and smart manufacturing systems, facilitating real-time data exchange and advanced analytics.

11. Conclusion

Converting synchro signals to PWM interfaces offers a practical solution for integrating legacy synchro systems with modern PWM infrastructure. By leveraging the advantages of PWM technology, organizations can enhance the precision, reliability, and efficiency of their synchronization systems. The implementation of synchro to PWM conversion can extend the usability of existing systems, reduce costs, and support scalable and flexible system designs. As technology continues to evolve, the adoption of synchro to PWM conversion is expected to increase, driving further innovation and efficiency in various applications.

12. References

- Analog Devices. “Understanding Synchro and Resolver Signals.” Analog.com.

- Texas Instruments. “Pulse-Width Modulation Basics.” TI.com.

- National Instruments. “Data Acquisition with PWM Devices.” NI.com.

- IEEE Standards Association. “IEEE Standard for Synchro/Resolver Converters.” IEEE.org.

- Aeroelectronics, Inc. “Synchro Converters for Aerospace Applications.” Aeroelectronics.com.