Enhance Data Connectivity: RS-422/232 to MIL-STD-1553 Interface

Abstract

Efficient communication across different protocols is a critical requirement in modern systems. The RS-422/232 to MIL-STD-1553 interface facilitates seamless integration between serial communication devices and the robust MIL-STD-1553 protocol used in mission-critical applications. This white paper explores the technical underpinnings, design considerations, applications, challenges, and benefits of implementing an RS-422/232 to MIL-STD-1553 interface. The goal is to provide a comprehensive guide for organizations aiming to enhance their data connectivity and streamline system integration.

1. Introduction

1.1 Overview of Protocols

Communication protocols define how data is transmitted and received. RS-422 and RS-232 are widely used in industrial and commercial applications for serial communication, while MIL-STD-1553 is a robust standard designed for military and aerospace systems.

1.2 The Need for Integration

With diverse systems often coexisting in complex infrastructures, interoperability between RS-422/232 and MIL-STD-1553 is crucial. The RS-422/232 to MIL-STD-1553 interface serves as a bridge, enabling the integration of legacy serial devices with modern MIL-STD-1553 systems.

2. Protocol Overview

2.1 RS-422 and RS-232 Protocols

RS-232

- Designed for point-to-point communication.

- Commonly used for short distances (up to 50 feet).

- Operates at slower data rates (up to 115 kbps).

- Single-ended signaling is prone to noise interference.

RS-422

- Uses differential signaling for better noise immunity.

- Supports higher data rates (up to 10 Mbps).

- Enables communication over longer distances (up to 4,000 feet).

2.2 MIL-STD-1553 Protocol

- Deterministic Communication: Ensures predictable data exchange.

- Redundancy: Dual channels provide fault tolerance.

- Robustness: Designed to withstand harsh environments.

- Topology: Implements a bus architecture with a single bus controller and multiple remote terminals.

2.3 Differences in Protocol Design

The technical disparities between RS-422/232 and MIL-STD-1553 necessitate a specialized interface for seamless data translation and synchronization.

3. RS-422/232 to MIL-STD-1553 Interface: Technical Insights

3.1 Functional Architecture

The RS-422/232 to MIL-STD-1553 interface typically includes:

- Input Modules: Receive RS-422 or RS-232 signals.

- Data Conversion Units: Translate serial protocol data into MIL-STD-1553 format.

- Output Modules: Transmit MIL-STD-1553-compatible data to the bus.

- Control Units: Manage data flow and handle error correction.

3.2 Conversion Process

- Signal Reception: Inputs from RS-422/232 devices are captured.

- Protocol Mapping: Data is reformatted to match MIL-STD-1553 specifications.

- Error Handling: Transmission errors are detected and corrected.

- Output Transmission: MIL-STD-1553 data is delivered to the bus.

3.3 Key Features

- Bidirectional Communication: Ensures data flow in both directions.

- Low Latency: Minimizes delays during conversion.

- Rugged Design: Operates in extreme environmental conditions.

4. Benefits of RS-422/232 to MIL-STD-1553 Interfaces

4.1 Seamless Integration

Enables legacy RS-422/232 systems to communicate with MIL-STD-1553 networks, ensuring compatibility.

4.2 Cost Efficiency

Avoids costly replacements by integrating existing devices with modern systems.

4.3 Enhanced Data Reliability

Combines the noise resistance of RS-422 with the fault tolerance of MIL-STD-1553.

4.4 Future-Proofing

Allows older devices to operate within contemporary and evolving infrastructures.

4.5 Simplified Maintenance

Streamlines monitoring and troubleshooting by consolidating communication protocols.

5. Applications

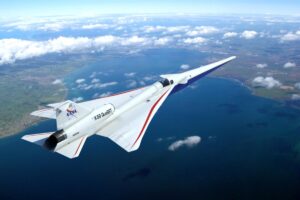

5.1 Aerospace

- Cockpit Instrumentation: Converts RS-422/232 sensor data for MIL-STD-1553 avionics systems.

- Black Box Recorders: Interfaces with RS-232 devices for data logging.

5.2 Defense

- Weapon Control Systems: Facilitates data exchange between RS-422/232 peripherals and MIL-STD-1553-based controllers.

- Command and Control Systems: Integrates legacy communication devices with MIL-STD-1553 networks.

5.3 Industrial Automation

- Factory Automation: Links RS-232/422-based PLCs with MIL-STD-1553 control buses.

- Robotic Systems: Converts data for robotic arms that use RS-422 communication.

5.4 Maritime Applications

- Navigation Systems: Integrates RS-232 instruments with MIL-STD-1553 onboard systems.

- Sonar Systems: Interfaces sonar equipment with MIL-STD-1553 networks.

5.5 Energy

- Renewable Energy Monitoring: Facilitates communication between RS-422/232 devices and MIL-STD-1553-based control systems.

- Smart Grids: Converts legacy RS-232 data for integration into MIL-STD-1553 monitoring frameworks.

6. Challenges in Implementation

6.1 Latency Concerns

Conversion processes can introduce delays that impact real-time applications.

6.2 Signal Integrity

Maintaining data fidelity during translation across protocols.

6.3 Protocol Mismatch

Adapting the structural and operational differences between RS-422/232 and MIL-STD-1553.

6.4 Environmental Stress

Ensuring reliable operation in environments with extreme temperatures, vibration, and EMI.

6.5 Scalability

Addressing future requirements without frequent hardware upgrades.

7. Addressing Challenges

7.1 Advanced Signal Processing

Incorporates error correction algorithms and signal conditioning.

7.2 Modular Design

Provides flexibility for future expansions and upgrades.

7.3 Real-Time Optimization

Utilizes high-speed processors to reduce latency during conversion.

7.4 Rugged Construction

Designs interfaces to meet MIL-STD environmental standards.

7.5 Compatibility Testing

Ensures seamless operation across diverse systems and configurations.

8. Emerging Trends

8.1 IoT Integration

Enables RS-422/232 devices to communicate with IoT platforms through MIL-STD-1553 networks.

8.2 Miniaturization

Reduces the size and weight of interface devices for deployment in compact environments.

8.3 AI-Driven Conversion

Uses machine learning to optimize protocol translation and improve efficiency.

8.4 Cybersecurity Enhancements

Integrates encryption and authentication features to protect sensitive data.

8.5 Wireless Connectivity

Enables wireless communication between RS-422/232 and MIL-STD-1553 devices, reducing cabling complexity.

9. Case Studies

9.1 Aircraft Modernization

A leading aerospace company used RS-422/232 to MIL-STD-1553 interfaces to integrate legacy flight sensors with advanced avionics systems, cutting upgrade costs by 40%.

9.2 Defense Systems Upgrade

A defense contractor deployed these interfaces to integrate RS-232 surveillance equipment with MIL-STD-1553-based command systems, enhancing situational awareness in critical missions.

9.3 Industrial Automation

An automotive manufacturer achieved seamless communication between RS-422-based robotic arms and MIL-STD-1553 production control systems, improving efficiency by 25%.

10. Best Practices for Implementation

10.1 Define Requirements

Identify system needs, including data rates, latency, and environmental conditions.

10.2 Select Reliable Hardware

Choose interfaces that meet industry standards and certifications.

10.3 Validate Performance

Test interfaces in operational environments to ensure compatibility and reliability.

10.4 Plan for Scalability

Consider future expansion and integration during initial implementation.

10.5 Focus on Security

Incorporate encryption and authentication mechanisms to protect against cyber threats.

11. Conclusion

The RS-422/232 to MIL-STD-1553 interface plays a pivotal role in bridging the gap between legacy serial communication devices and robust MIL-STD-1553 networks. By enabling seamless integration, these interfaces help organizations optimize their systems for improved efficiency, cost savings, and future-proofing. As technology evolves, this integration solution will continue to be instrumental in diverse industries, ensuring robust data connectivity and enhanced performance.