Ensure Reliability with Advanced 1553 Testers

Introduction

In modern avionics and military systems, data communication is vital to ensure that every component performs its task reliably and in harmony with other subsystems. The MIL-STD-1553 data bus standard is a long-standing protocol developed to address the stringent needs of such mission-critical environments. While its deterministic, fault-tolerant communication model makes it a preferred protocol in aircraft, spacecraft, and defense vehicles, maintaining its reliability requires rigorous testing. This is where 1553 testers become indispensable. These specialized tools are designed to verify signal integrity, ensure protocol compliance, detect faults, and support both production and maintenance operations. This white paper delves into the importance of 1553 testers, exploring their functions, design considerations, use cases, and emerging trends in testing technology.

1.1 Historical Context

Developed in the 1970s by the U.S. Department of Defense, MIL-STD-1553 was originally intended to standardize data exchange among avionics systems. Its dual-redundant bus architecture and deterministic scheduling were designed for systems that require high reliability and fault tolerance.

1.2 Technical Specifications

MIL-STD-1553 operates at 1 Mbps using Manchester encoding and transformer-coupled connections for improved noise immunity and electrical isolation. Devices are classified as Bus Controllers (BC), Remote Terminals (RT), or Bus Monitors (BM). Communication occurs in a command/response format regulated by the BC.

1.3 Applications in Modern Systems

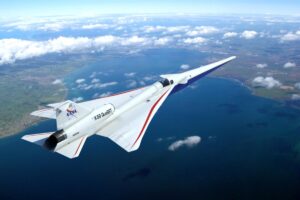

Despite its age, MIL-STD-1553 remains widely used in aircraft (fixed-wing and rotary), satellites, launch systems, naval ships, and ground combat vehicles. The protocol’s reliability under stress and redundancy design make it ideal for mission-critical data transfer.

2.1 Functional Objectives

1553 testers are employed to assess compliance with protocol standards, verify electrical signal characteristics, and simulate real-world scenarios. They can emulate BCs, RTs, and BMs, offering a comprehensive environment to test all aspects of a MIL-STD-1553 network.

2.2 Importance in Development and Maintenance

During the development phase, 1553 testers help validate new designs, ensuring devices behave as expected. In operational settings, they identify faults, measure performance degradation, and assist in predictive maintenance to avoid system failures.

2.3 Types of 1553 Testers

- Portable Field Testers: Ruggedized for use in military environments, ideal for onsite diagnostics.

- Benchtop Test Systems: Used in labs for high-detail analysis and debugging.

- Embedded Test Tools: Integrated into systems for continuous or periodic testing during operation.

3.1 Signal Integrity Verification

Testers verify waveform characteristics like rise/fall times, voltage levels, and signal symmetry. They help identify noise, jitter, and signal reflections that could compromise data integrity.

3.2 Protocol Compliance Testing

These tools ensure that messages comply with MIL-STD-1553 command/response formatting, timing constraints, and word structure. Any deviation from protocol can result in data loss or miscommunication.

3.3 Fault Injection and Error Analysis

Advanced testers support fault injection, allowing engineers to evaluate how systems respond to anomalies like missing responses, parity errors, or timing violations. This improves system robustness.

3.4 Bus Load Simulation

To assess how systems behave under high-traffic conditions, testers simulate bus loads, validating how multiple devices interact under stress and identifying bottlenecks.

3.5 Performance Metrics and Logging

Testers provide logs of message sequences, latency, retries, and error rates. These metrics are critical for performance tuning and reliability assessments.

4.1 Test Interface Cards

Typically installed in PCs or dedicated testers, these interface cards connect to 1553 buses and handle signal processing. They support multiple roles (BC, RT, BM) and can operate on dual-redundant buses.

4.2 Signal Conditioning and Coupling

To match the electrical requirements of MIL-STD-1553, testers include transformer coupling, isolation, and protection circuits, ensuring safe and accurate signal injection and measurement.

4.3 User Interface Software

Graphical software allows engineers to script tests, visualize traffic, and interpret results. Drag-and-drop interfaces and timeline views improve usability and troubleshooting speed.

4.4 Automation APIs

For regression testing or integration with CI/CD workflows, modern testers offer APIs (e.g., Python, C++, LabVIEW) that enable automated test execution and data extraction.

5.1 Design and Development

In early stages, testers help verify the logic of new RTs or BCs. They ensure the hardware complies with electrical specs and protocol formats.

5.2 Manufacturing and Production

During production, testers validate each unit with repeatable test sequences. Faulty components are identified before shipment, ensuring only compliant devices are deployed.

5.3 Maintenance and Troubleshooting

Field service teams use portable testers to diagnose failed links, check wiring integrity, and validate performance. Maintenance routines rely on testers to ensure ongoing functionality.

5.4 Certification and Compliance

Before deployment in military platforms, systems must pass rigorous compliance tests. Certified testers support these assessments with verified procedures and reports.

6.1 AI-Driven Fault Analysis

Machine learning algorithms are being integrated to detect patterns and anomalies in bus behavior, helping predict failures before they occur.

6.2 Cloud-Connected Testers

New solutions enable remote access to test equipment, allowing experts to diagnose systems from central locations and update test scripts globally.

6.3 Integrated Cybersecurity Testing

With rising concerns about cyber threats in avionics, testers are being enhanced to evaluate data integrity, detect spoofed messages, and verify encryption schemes.

6.4 Miniaturization and Wearables

Field testers are becoming smaller and more ergonomic, with touchscreen displays and wearable formats that improve technician mobility and ease of use.

6.5 Hybrid Protocol Support

Some testers now support additional protocols like ARINC 429, CAN, or Ethernet, enabling cross-protocol analysis and integration testing in heterogeneous environments.

7. Considerations for Choosing a 1553 Tester

7.1 Test Coverage

Choose testers that support multiple roles and comprehensive test cases. Full simulation and monitoring capabilities are essential for deep diagnostics.

7.2 Environmental Suitability

For field work, the tester must be rugged, temperature-resistant, and compliant with MIL-STD-810 or similar standards.

7.3 User Experience

Intuitive interfaces and strong vendor support can dramatically reduce the learning curve and increase productivity.

7.4 Software Ecosystem

Evaluate the scripting capabilities, API support, and integration with lab tools or avionics test benches.

7.5 Cost and Lifecycle

Consider both upfront cost and long-term support. Reputable vendors provide firmware updates, training, and calibration services.

8.1 Early Integration

Integrate testing in the earliest design phases to catch errors when they are cheapest to fix.

8.2 Standardized Test Scripts

Use reusable scripts for consistency across teams and testing phases. Version control helps maintain traceability.

8.3 Regular Calibration

Periodically calibrate testers to maintain measurement accuracy and ensure compliance.

8.4 Root Cause Analysis Workflows

Define standard procedures for diagnosing test failures to reduce downtime and ensure consistent resolution.

8.5 Continuous Improvement

Use test data to refine design practices, component selection, and system architecture for improved reliability.

Advanced 1553 testers are essential tools for ensuring the integrity, compliance, and performance of mission-critical avionics systems. From development to deployment, they provide insights that prevent failures, extend system life, and enhance interoperability. As technologies evolve, so too will the capabilities of these testers—supporting more intelligent diagnostics, remote operation, and integrated cybersecurity features. Choosing the right tester and using it effectively is not just a technical decision—it’s a strategic one that ensures the safety, reliability, and success of aerospace and defense missions.