Altitude Testing in MIL-STD-810

Table of Contents

- Introduction

- Understanding MIL-STD-810

- Importance of Altitude Testing

- Altitude Testing Methods in MIL-STD-810

- Method 500: Altitude

- Method 500.1: Altitude – Low Pressure (Simulated)

- Method 500.2: Altitude – Decompression

- Application of Altitude Testing

- Conclusion

- References

1. Introduction

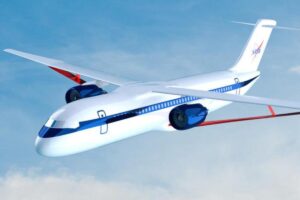

Altitude presents unique challenges for product performance and reliability due to changes in atmospheric pressure and oxygen levels. Whether it’s aerospace equipment, outdoor gear, or electronic devices, understanding how products perform at different altitudes is crucial for ensuring their functionality in high-altitude environments. MIL-STD-810 provides guidelines for altitude testing, enabling manufacturers to assess product resilience under varying atmospheric conditions. This white paper explores the significance of altitude testing in MIL-STD-810 and delves into the prescribed methods for evaluating product performance at different altitudes.

2. Understanding MIL-STD-810

MIL-STD-810, also known as “Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests,” is a set of guidelines developed by the United States Department of Defense to evaluate the environmental suitability and performance of military equipment and systems. It encompasses various environmental factors, including altitude, temperature, humidity, shock, vibration, and more, providing standardized testing procedures to ensure product durability and reliability in diverse operational environments.

3. Importance of Altitude Testing

Altitude testing is essential for assessing how products perform in high-altitude environments where atmospheric pressure and oxygen levels decrease significantly. Changes in altitude can affect material properties, thermal management, combustion processes, and electronic functionality, leading to performance degradation or failure if not adequately addressed. By subjecting products to altitude testing according to MIL-STD-810 specifications, manufacturers can identify potential vulnerabilities, optimize designs, and ensure product functionality and safety at different altitude levels.

4. Altitude Testing Methods in MIL-STD-810

MIL-STD-810 outlines several methods for altitude testing to simulate low-pressure environments, decompression scenarios, and other altitude-related conditions. The primary altitude testing methods include:

Method 500: Altitude Method 500 specifies procedures for subjecting test items to various altitude levels to evaluate their performance under reduced atmospheric pressure conditions. This method simulates altitude changes encountered during transportation, storage, or operation in high-altitude environments.

Method 500.1: Altitude – Low Pressure (Simulated) Method 500.1 focuses on simulating low-pressure environments using altitude chambers or vacuum chambers. It assesses product resilience to reduced atmospheric pressure conditions, including the effects of altitude on material properties, seals, and functionality.

Method 500.2: Altitude – Decompression Method 500.2 addresses altitude decompression testing, which involves subjecting test items to rapid or gradual changes in pressure to simulate decompression scenarios experienced during ascent or descent. This method evaluates product performance under altitude-related pressure changes and assesses the effectiveness of pressure relief mechanisms.

5. Application of Altitude Testing

Altitude testing per MIL-STD-810 is applicable across various industries, including aerospace, defense, automotive, outdoor equipment, and consumer electronics. Manufacturers use these testing methods to validate product designs, identify potential weaknesses, and ensure compliance with regulatory standards. By conducting thorough altitude testing, companies can mitigate risks associated with altitude-related performance issues, optimize product designs for high-altitude environments, and enhance customer satisfaction by delivering reliable and durable products capable of operating at different altitude levels.

6. Conclusion

Altitude testing is a critical aspect of product development and validation, particularly for applications intended for use in high-altitude environments. By adhering to altitude testing guidelines outlined in MIL-STD-810, manufacturers can assess product resilience under reduced atmospheric pressure conditions, identify design improvements, and ensure reliable operation at different altitude levels. Whether for military, aerospace, or commercial applications, implementing comprehensive altitude testing procedures is essential for enhancing product durability, performance, and safety in high-altitude environments.

7. References

- MIL-STD-810: Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests.

- “Environmental Testing Procedures for Military Equipment.” Defense Technical Information Center.

- ASTM International: Standards for Environmental Testing and Simulation.

- DoD Environmental Testing Guide.