Temperature Testing per MIL-STD-810

Table of Contents

- Introduction

- Understanding MIL-STD-810

- Importance of Temperature Testing

- Temperature Testing Methods in MIL-STD-810

- Method 501: High Temperature

- Method 502: Low Temperature

- Method 503: Temperature Shock

- Application of Temperature Testing

- Conclusion

- References

1. Introduction

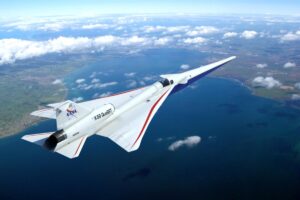

Temperature fluctuations pose significant challenges to product performance and reliability across various industries. Whether it’s electronics, automotive components, or aerospace systems, ensuring products can withstand extreme temperatures is critical. MIL-STD-810 provides comprehensive guidelines for temperature testing, enabling manufacturers to evaluate their products’ ability to operate reliably under diverse temperature conditions. This white paper explores the importance of temperature testing per MIL-STD-810 and delves into the prescribed methods for assessing product resilience under extreme temperature environments.

2. Understanding MIL-STD-810

MIL-STD-810, also known as “Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests,” is a set of guidelines developed by the United States Department of Defense to evaluate the environmental suitability and performance of military equipment and systems. It covers a wide range of environmental factors, including temperature, humidity, shock, vibration, and more, providing standardized testing procedures to ensure product durability and reliability in challenging operational environments.

3. Importance of Temperature Testing

Temperature testing is essential for assessing the performance and reliability of products exposed to extreme temperature conditions, such as those encountered in desert climates, arctic regions, or within the confines of aircraft and spacecraft. Extreme temperatures can lead to material degradation, thermal expansion or contraction, electrical malfunctions, and other adverse effects, compromising product functionality and safety. By subjecting products to temperature testing according to MIL-STD-810 specifications, manufacturers can identify vulnerabilities, optimize designs, and ensure product integrity under a range of operating conditions.

4. Temperature Testing Methods in MIL-STD-810

MIL-STD-810 outlines several methods for temperature testing to simulate high and low temperature environments, as well as rapid temperature transitions. The primary temperature testing methods include:

Method 501: High Temperature Method 501 specifies procedures for subjecting test items to high temperature conditions, typically ranging from 50°C to 160°C (122°F to 320°F). This method evaluates the effects of sustained high temperatures on product performance, materials, and components.

Method 502: Low Temperature Method 502 outlines procedures for exposing test items to low temperature conditions, typically ranging from -73°C to -51°C (-100°F to -60°F). This method assesses product resilience to cold environments, including the effects of freezing temperatures on materials and functionality.

Method 503: Temperature Shock Method 503 focuses on temperature shock testing, which involves rapid and repetitive temperature transitions between high and low extremes. This method evaluates the ability of products to withstand thermal cycling and abrupt temperature changes without experiencing performance degradation or structural failure.

5. Application of Temperature Testing

Temperature testing per MIL-STD-810 is applicable across various industries, including defense, aerospace, automotive, electronics, and consumer goods. Manufacturers use these testing methods to validate product designs, identify potential weaknesses, and ensure compliance with regulatory standards. By conducting thorough temperature testing, companies can mitigate risks associated with temperature-related failures, optimize product performance, and enhance customer satisfaction by delivering reliable and durable products capable of withstanding extreme environmental conditions.

6. Conclusion

Temperature testing is a critical aspect of product development and validation, particularly for applications exposed to extreme temperature environments. By adhering to temperature testing guidelines outlined in MIL-STD-810, manufacturers can evaluate product resilience under high and low temperature conditions, identify design improvements, and ensure reliable operation across diverse operating environments. Whether for military, aerospace, or commercial applications, implementing comprehensive temperature testing procedures is essential for enhancing product durability, performance, and customer satisfaction.

7. References

- MIL-STD-810: Department of Defense Test Method Standard for Environmental Engineering Considerations and Laboratory Tests.

- “Environmental Testing Procedures for Military Equipment.” Defense Technical Information Center.

- ASTM International: Standards for Environmental Testing and Simulation.

- DoD Environmental Testing Guide.